How to Select the Optimal PM Fiber Patch Cord for Your Sensing System

In advanced photonic systems like fiber optic sensing, interferometry, and quantum optics, the polarization state of light is not just a property—it’s the signal. Uncontrolled polarization changes directly translate into system noise, drift, and failure. The Polarization-Maintaining (PM) fiber patch cord, often treated as a simple cable, is in fact a critical optical component that determines the performance ceiling of your entire setup.

Selecting the right PM patch cord requires careful consideration of its core attributes. This guide outlines the key technical factors to inform your decision.

1. Fiber Type: Match the Core “DNA”

PM fiber maintains polarization via internal stress regions (e.g., Panda, Bow-Tie). The fundamental rule is to match the fiber type of your patch cord with the PM fiber inside your core components (laser, integrated optic chip, sensing coil). Mismatch is a primary source of polarization cross-talk and performance degradation.

2. Polarization Extinction Ratio (PER): The Key Metric

PER, measured in dB, quantifies how well the patch cord preserves linear polarization. It’s the ratio of power in the desired polarization axis to the power in the orthogonal axis. Higher PER (e.g., >25 dB) is crucial for sensitive applications like fiber optic gyroscopes (FOGs) or coherent detection. Request the end-to-end, guaranteed minimum PER from the manufacturer.

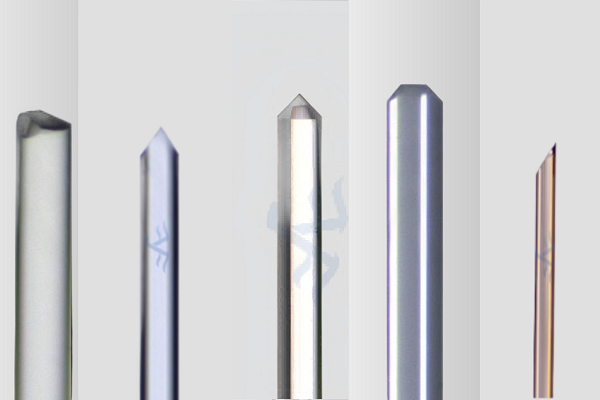

3. Connectors and Keying: Ensure Precise Alignment

- Connector Type: Choose FC/APC or SC/APC angled connectors for high Return Loss (>55 dB) to minimize back reflections in interferometric systems.

- Alignment Key: The connector key must align with the slow (or fast) axis of the fiber. Precise, stable keying is essential for repeatable low-loss, high-PER connections. Confirm the key orientation standard with your supplier.

4. Mechanical & Environmental Reliability

The cord must perform consistently under real-world conditions.

- Robust Jacketing: Strengthened armoring protects against bending and crushing.

- Temperature Performance: Verify operational temperature range and PER stability over temperature swings relevant to your application.

- Test Data: Reputable suppliers provide test reports for insertion loss, PER uniformity, and durability.

Making the Informed Choice

Translate specifications into system-level benefits:

- For maximum stability in lab settings, prioritize highest PER and repeatability.

- For rugged, space-constrained integration, focus on compact form, robust keying, and high plug-repeatability.

- For volume production, emphasize parameter consistency and traceability across batches.

Conclusion

Selecting a PM patch cord is an investment in your system’s integrity, precision, and long-term stability. It should be a deliberate component choice, not an afterthought.

At Feiyi Optics, we engineer PM fiber patch cords to meet the stringent demands of high-end sensing and imaging systems. Our products are characterized by superior PER, exceptional reliability, and precise documentation.

Explore our comprehensive range of Polarization-Maintaining Fiber Patch Cords and their detailed specifications here: Feiyi Optics – PM Fiber Patch Cords