Lensed Fibers: Precision Tools for Efficient Light Coupling

In modern photonic systems, efficiently coupling light between optical fibers and other components (like laser diodes, photonic chips, or detectors) is a critical challenge. Standard flat-cleaved fibers often lead to significant coupling loss due to mode field mismatch and Fresnel reflection. This is where lensed fibers become indispensable. By shaping the fiber tip into precise micro-optical structures, they dramatically improve coupling efficiency and enable advanced functionalities.

At Feiyi OEO, we specialize in engineering a range of high-precision lensed fibers to meet diverse and demanding application requirements.

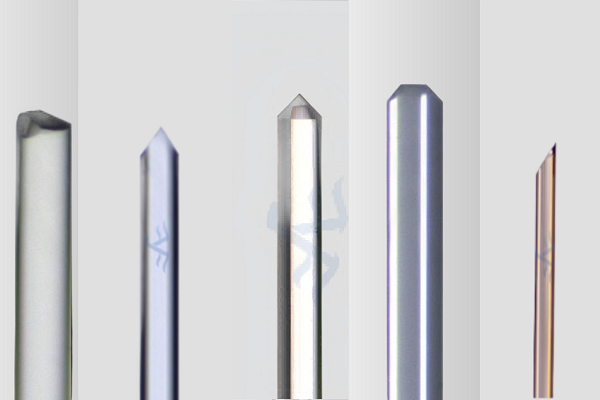

Understanding Lensed Fiber Types and Their Applications

The performance of a lensed fiber is primarily determined by its tip geometry. Selecting the right type is crucial for optimizing your system.

| Lens Type | Key Characteristics & Design | Typical Applications & Advantages |

|---|---|---|

| Tapered Lensed Fiber | The fiber end is heated and stretched to form a gradual, conical taper terminating in a small, rounded tip. | Free-space coupling into photonic integrated circuits (PICs) or between fibers. Offers a good balance of working distance and spot size control. |

| Wedge Lensed Fiber | Features a single angled facet, often polished at 45° or other specific angles, creating a reflective surface. | Deflecting the optical path by 90°. Ideal for side-firing applications in medical devices, sensing, or compact module assembly. |

| Two-Faceted Lensed Fiber | The tip is polished into two intersecting angled facets, forming a sharp wedge or roof-like structure. | Similar to wedge fibers but often used for more precise beam deflection or splitting. Useful in interferometric setups. |

| Angled Lensed Fiber | The fiber end is polished at a standard angle (common 8°) to the fiber axis, but retains a flat or lensed surface. | Primarily used to minimize back reflections (ultra-low return loss) when coupling to laser diodes or other reflective surfaces, preventing system instability. |

| Four-Faceted / Pyramidal Lensed Fiber | The tip is polished into a four-sided pyramid, creating a very fine, sharp point. | Extremely high-resolution near-field scanning optical microscopy (NSOM/SNOM). The sharp tip allows for light interaction with sub-wavelength spatial resolution. |

A Practical Guide to Selecting Your Lensed Fiber

Choosing the correct lensed fiber involves analyzing your system’s key parameters. Follow this decision flow:

- Define the Primary Goal:

- Maximize Coupling Efficiency? → Focus on Tapered or precisely shaped spherical lenses.

- Change Beam Direction (e.g., 90° turn)? → A Wedge or Two-Faceted fiber is the standard solution.

- Suppress Back Reflections? → An Angled tip (often with anti-reflective coating) is mandatory.

- Enable High-Resolution Probing? → The Pyramidal (Four-Faceted) fiber is designed for NSOM applications.

- Specify Key Optical Parameters:

- Working Distance (WD): The distance from the fiber tip to the component where the beam is focused. Tapered fibers offer flexible WD; wedge fibers have a very short WD from the facet.

- Spot Size / Beam Profile: Determines how well the output beam matches the mode field of the target component. This is directly controlled by the lens shape and polishing process.

- Numerical Aperture (NA): Affects the convergence/divergence angle of the output beam.

- Return Loss: Critical for laser-based systems. Specify your required value; angled polishing is the primary method to achieve >60 dB return loss.

- Consider Mechanical & Environmental Requirements:

- Fiber Type: Single-mode (SMF-28e, PM) or multimode? We provide lensing on various fiber types, including Polarization-Maintaining (PM) fibers for systems sensitive to polarization state.

- Connector Type: FC/PC, FC/APC, LC, or bare fiber?

- Coating: Optional metallic coating for durability in harsh environments or for NSOM probes.

Why Partner with Feiyi OEO for Lensed Fibers?

Beyond standard options, our expertise lies in delivering reliable, customized solutions:

- Deep Application Knowledge: We collaborate with you to translate your system requirements into precise optical specifications.

- Precision Manufacturing: Our controlled polishing and shaping processes ensure consistent performance and high reliability across every unit.

- Full Customization: We tailor the lens geometry, fiber type, connector, and coatings to create the optimal component for your unique application.

Explore our detailed product pages to see specifications and learn more:

- Angled Lensed Fiber

- Four-Faceted (Pyramidal) Lensed Fiber

- Tapered Lensed Fiber

- Two-Faceted Lensed Fiber

- Wedge Lensed Fiber

- Browse the full collection: Lensed Optical Fibers Category

Let’s optimize your coupling efficiency. Contact our engineering team to discuss your project needs and request custom prototypes.

#LensedFiber #FiberOptic #Photonics #OpticalCoupling #PIC #LaserDiode #NSOM #PrecisionOptics #FeiyiOEO